|

| September 18, 2012 | Volume 08 Issue 35 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Engineer's Toolbox:

Maximizing steam turbine/compressor performance with precise torque monitoring at the coupling

By Daniel Phillips, Trevor Mayne, and Mark Ellul

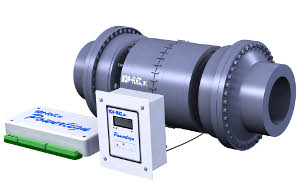

Emerson Industrial Automation's Kop-Flex Powerlign Torque Monitoring System provides accuracy to within 1% of full-scale torque, utilizing single-channel phase displacement.

All turbo machinery is subject to degradation that, over time, will affect the system's efficiency and operational performance. Precise monitoring of turbo machinery performance with continuous torque-monitoring systems can be used to identify gradual efficiency loss, allowing a more focused maintenance scope to be developed to return the system to its optimum operation and efficiency.

Torque monitoring based on heat balance, energy balance, and other methods utilizes numerous parameters such as pressure, temperature, flow rate, gas composition, etc., that require precise instrumentation to properly measure with low uncertainty.* However, phase displacement technology can be used to accurately measure torque directly at the coupling to within 1% of full-scale torque, a combination of all electrical and mechanical sources of error. This accuracy provides the lowest amount of uncertainty when computing efficiency, compared to alternative methods.

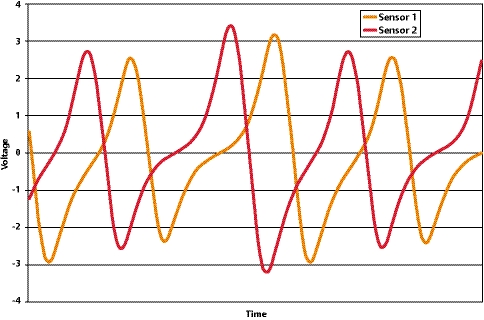

A system of this type was recently installed on a cracked-gas compressor train at Qenos Olefins in Australia to determine the causes of a power limitation. The Kop-Flex Powerlign system utilizes phase displacement technology for long-term reliability, eliminating need for re-calibration. Two rings with pick-up teeth are installed on a torsionally soft spacer, and are intermeshed at a central location. Two monopole sensors, 180° apart, are mounted on the coupling guard. As the coupling rotates, the ferromagnetic teeth create an AC voltage waveform in the sensor coil, which is digitally processed using known calibration parameters. Because of the intermeshed pick-up teeth, the system is referred to as a single-channel phase-displacement system, producing two independent torque measurements (Figure 1).

Figure 1. The Powerlign system produces two independent torque signals.

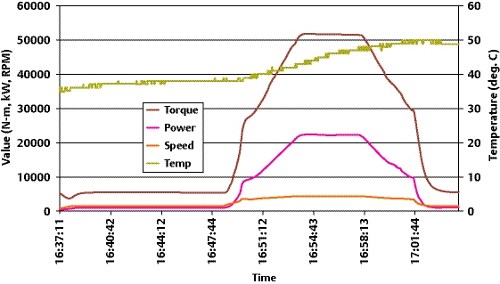

The Powerlign system will output torque, power, speed, and temperature, which can be easily integrated with any DCS system (Figure 2).

Figure2. Typical output from Powerlign system.

At the Olefins plant, the operating cycle of the steam-driven, cracked-gas compressor train is 7 to 8 years. During this cycle, the plant reaches production limitations because this compressor train encounters a power limit. To determine the cause of the power limit as "turbine fouling" or "compressor fouling" or a combination of both was not confidently possible with the instrumentation installed. The cause had long been the subject of an engineering debate between the Machinery group, Process Engineering group, and Operations department. One option to add more power by upgrading the turbine power rating from 7.5 MW to 9 MW was investigated. This required a capital investment of $2 million. The plant elected to defer this investment and instead installed a torque meter at the major 8-year shutdown.

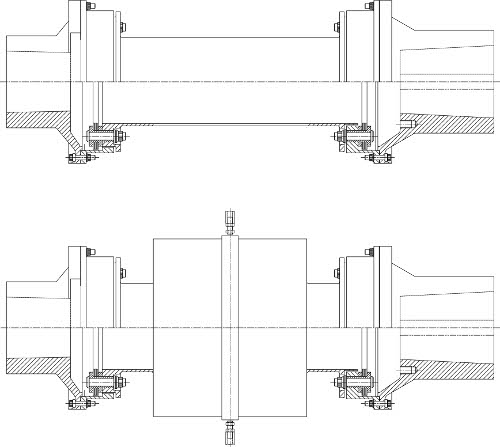

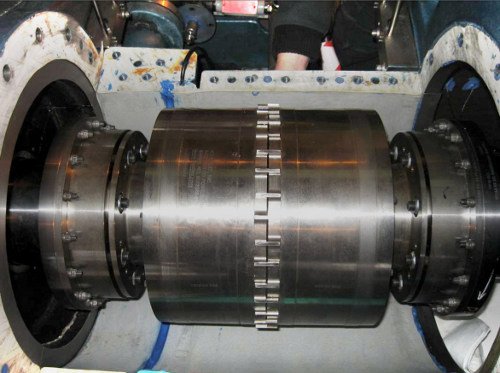

The installation involved replacing the existing coupling spacer and flexible halves with a "drop-in" torque meter and integral flexible elements (Figure 3).

Figure 3. Existing coupling arrangement at top, and with retrofitted Smart Spacer, bottom.

The torque meter assembly was dynamically balanced to API standards, so it was not necessary for the user to return any coupling components for the retrofit. The coupling guard was modified so that the two variable-reluctance sensors could be installed, completing the mechanical installation (Photographs 1 to 3).

Photo 1. Completed mechanical installation at Qenos Olefins.

Photo 2. Smart Spacer retrofited at Qenos Olefins plant.

Photo 3. Sensor installation in coupling guard.

On restarting the plant and having completed a number of compressor efficiency improvements, the torque meter clearly showed the 7.5-MW turbine did not require a power uprate and that the major power losses were coming from the compressor. The torque meter also allowed online tuning of the seal gas system of the compressor to establish the lowest power draw from the recycles that the seal system introduces. An additional 200 KW of power was reduced from the turbine load, with the manual adjustments made on the seal gas system.

The torque meter is now being used to monitor turbine steam fouling issues and process-related compressor fouling so that the corrective online washing can be activated as soon as issues arise.

The historical data collected from the torque meter will also provide a baseline of mechanical loading through the drive drain of the cracked-gas compressor over time. This data will be used to determine if increases in the maximum continuous operating speed rating of the compressor and the turbine can be accomplished at minimal costs. This would achieve increases in the operating envelope of the compressor.

The value of the torque meter has justified the installation of a second system for the Olefins plant's second steam cracking plant turbine/compressor train in October 2012.

For more information, an interactive page-flip version of Emerson's Industrial Coupling Catalog is online at www.emersononlinecatalog.com. Printed copies can be ordered at www.emerson-ept.com.

*[Kurz, R., Brun, K., and Legrand, D., 1999, "Field Performance Testing of Gas Turbine Driven Centrifugal Compressors," Proceedings of the 28th Turbomachinery Symposium, Turbomachinery Laboratory, Texas A&M University, College Station, Texas, pp. 216-220.]

About the authors

Daniel Phillips is manager, field service engineering, Kop-Flex, Emerson Industrial Automation, Hanover, MD. Email: Daniel.phillips@emerson.com.

Trevor Mayne is a machinery engineer, Qenos Olefins Australia. Email: trevor.mayne@qenos.com.

Mark Ellul is Qenos I & E Specialist, Qenos Olefins Australia, Email: Mark.Ellul@qenos.com.

About Emerson Industrial Automation

Emerson Industrial Automation, a business of Emerson, has products that include alternators, electric motors and drives, electrical distribution devices and mechanical power transmission, fluid automation and ultrasonic joining solutions. Emerson brands include Appleton, ASCO, Branson Ultrasonics, Browning, Control Techniques, Kop-Flex, Leroy-Somer, McGill, Morse, Numatics, O-Z/Gedney, Rollway, Sealmaster, SSB Wind Systems, and System Plast.

Published September 2012

Rate this article

View our terms of use and privacy policy